Ultra-high purity water (18.2 megohm-cm resistivity) at an very economical price; water purification systems maximizing pure water production through application of the laboratory grade deionization resins used in our specialty deionization cartridges. SpectraPure Membranes have 98.0+% average rejection and produce 90 GPD & 180 Gallons Per Day.

New Super Capacity 2-stage Deionizer

First Stage revolutionary MAXCAP DI with 3.5x capacity of other mixed-beds – Lower your DI production costs by over half!

Second DI stage is the DI cartridge that pioneered silica removal – SpectraPures Silica-Buster Cartridge.

The best pre-filtration available:

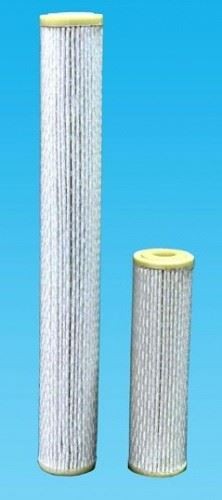

Ultra-high efficiency 0.5 micron Sediment Pre-Filter. Our best sediment filter for improved particle removal and long term performance. Not a cheap import.

1/2 micron Carbon Block Pre-Filter with a 20,000 gallon chlorine removal capacity. Our best carbon block Chloramine eater. All the carbon block you ever need, period.

5 stage RO/DI System

Clear housings and pressure gauge

SpectraSelect Ultra-High Rejection RO Membrane

2 x Dual Inline TDS meters, one to monitor RO Membrane performance and one to monitor MAXCAP® and Silica-Buster performance to signal when replacement is required.

Filter wrench

Effective on well water and colloidal silica

Dimensions: 20″ x 7″ x 16″

SpectraPure® MAXCAP RO/DI Systems incorporate our SpectraPure Membrane that produces 180 GPD. It also is the highest rejection rate available at 98% (180 GPD @ 60 psi & 77 degF). Used in combination with our MAXCAP DI and silica-removal deionizing cartridges, this system provides the ultimate removal of algae promoting substances, including colloidal silica, and the longest deionizing cartridge life, significantly reducing the cost of operation. This is water purification at its best, an RO/DI system designed to continuously produce economical ultra-pure water.

Dual stage DI for true “18.2 meg-ohm resistivity laboratory grade water” . This super capacity DI system consists of a newly developed MAXCAP DI Cartridge, with over three times as much contaminate removal capacity than any other Mixed-Bed DI cartridge. The final stage consists of our Silica-Buster DI cartridge, with two, dual inline electronic purity monitors to determine the performance of the RO membrane as well as the DI exhaustion points. While competitors claim ZERO TDS, dont be fooled by limitations of most inexpensive DI Systems. Besides, it just makes sense. two stages of high quality DI cartridges definitely will produce higher purity water more reliably over the life of the cartridges than any single stage.

The MAXCAP RO/DI is available with either a FilmTecT 90 or 180 gallon per day membrane.

MAXCAP RO/DI Systems are equipped with the finest pre-filtration 0.5 micron MicroTec pre-filters, and 20,000 ppm-gallon chlorine/chloramine capacity carbon block pre-filters. Clear filter housings and a standard pressure gauge provide better visibility of system performance. No more guessing about plugged pre-filters. Also included is a filter wrench and a 3/4″ garden hose adapter.

Our premium grade filters (as used in the MAXCAP RO/DI) are a significant upgrade in performance and capacity. Each of our premium grade filters has been extensively tested in the worst case locations to insure performance, capacity, and reliability. If you have excellent tap water (a rarity these days, but it still happens in some places in the US ) you may be able to scrimp on pre-filtration, but we see that as the exception in most locations, and thus recommend you purchase the best pre filtration you can afford. As important as pre filtration is to removal of contaminants and the life of your expensive RO membrane (and subsequently the life of your DI cartridges) we think that for ultimate performance and lower cost of ownership over the production life of your membrane that you should always use the best pre-filtration available.

Caution: DI cartridge life is greatly reduced when operated on low pH waters or water with high CO2 levels. Aeration or

de-gassification of RO product water is recommended for removal of carbon dioxide prior to the DI section.