The Ultra Reef UCS range of calcium reactor integrates and maintains the level of calcium and alkalinity within an aquarium.

The reactor is filled with calcium-based media and continuously filled with aquarium water that flows out slowly.

Using the CO2 provided by the connected vessel, it lowers the pH of the water that recirculate in its interior to the point

of dissolution of the medium which slowly consumes and release carbonate and calcium ions (and other elements) constantly in the aquarium.

Performance

Tank size For aquariums up to 500 lit

Pump SICCE Syncra 1.5

Load capacity ~ 3 lit

Power consumption ~ 20 W

Dimension

Base plate 13×19 cm (5.1×7.5″)

Height 56 cm (22″)

Height with connection 58 cm (22.8″)

Suggested to be installed in sump, but can be mounted outside.

Power

Standard 230-240V 50Hz

On request 110-120V 60Hz

Required Accessories

Water load pump or charge pipeline deviation (included D.6 mm connection hose)CO2 vessel and pressure valve (included D.6 mm connection hose)

Product Features

Thanks to the experience gained in more than half a century in the fluid dynamics, in our product we propose the following solutions:

An efficient and economic integration system

Our calcium reactors are a simple and functional device for the maintenance of the values of calcium,

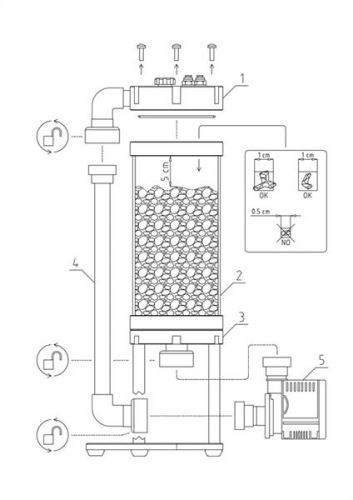

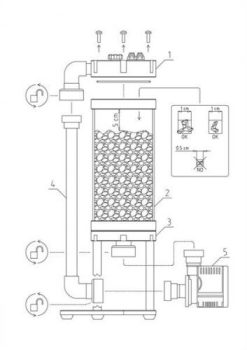

magnesium and kh in marine reef aquariums. The lower perforated plate diffuses the flow of water,

ensuring a constant and homogeneous recirculation in the chamber and in contained material.

This solution reduces the risk of medium compaction and allows it to be exploited until exhaustion.

Modern design and smart pump positioning

The pump is housed on the bottom of the reactorr to reduce the lateral ingots. This solution significantly reduces power consumption

and the risk of dry operation by preventing accumulation of carbon dioxide bubbles in pump housing.

Pump submerged position prevent its harmful overheating while the reactor chamber remain raised by the water of the sump,

preventing the heat generated by the melting process heating the aquarium water.

Strong and durable structure

Most of the reactor is made with PVC components machined from solid and bolted together.

The absence of small moving parts gives the structure an excellent solidity.

The covers use a system of silicone gaskets O-ring and are tighten by titanium screws,

while the rapid connection fittings with O-ring seal allow quick and safe installation of discharge and load hoses.

Integrated CO2 recovery system

The recirculation pipe is installed in the upper part of the conical cover and performs the function of recovering CO2.

This solution significantly reduces the consumption of carbon dioxide and limits the emission of the same in the aquarium.

Complete of connection hoses

Reactor is supplied complete ofwater load hose, water drain hose with regulation valve, CO2 load hose, bubble counter and pH probe attack.

Easy and thorough maintenance

Our product can be disassembled virtually in every single component.

The generous thicknesses of the materials used ensure excellent resistance during all maintenance,

while small component reduction facilitates cleaning and replacement of individual worn components.

Design, quality and performance

During product development, we start from what the aquarist needs. The construction choices we use always have a practical logic

and often depart from a direct need, which could not be fully satisfied by products currently available on the market.

Made in Italy product

Our company was founded in 1957 and since then has produced hydraulic equipment and flow devices of the highest quality without compromise.

In our factory, we work with care and passion that has always characterized Italians companies.

Our success is based on customer satisfaction through efficient processing and delivery of high quality products at competitive price.

CNC machining of full blocks of PVC

We perform all of the internal development of our products in house, from design to production.

Our brand guarantees a deep and careful evaluation of the operation, both technically and aesthetically,

thanks to the CNC machining of full blocks of PVC

Research and development without reliance

Thanks to continuous research for innovations and new technologies to be used in manufacturing process

we are always at the forefront in development of our products.

Flexibility and speed of response to recent searches in the sector guarantee our products excellent performance.

Anticorrosion Titanium screws

Screws DIN7985 are made in Titanium G2, resistant to corrosion caused by seawater.

To give the best even in smaller components.

ISO 9001 Quality certification

The goal of business excellence can be achieved only if management and employees assume joint responsibility for quality,

standardized methods and instruments and processes are continuously improved.

Our company is certified and complies with the ISO 9001, the most commonly used international standard that provides a framework for Quality Management Systems.